Quicklinks

Search Data Sheet

Protective Coatings Webinar Series

Explore our upcoming and archived webinars.

High Performance Flooring

Explore our newly organized resinous flooring product portfolio.

FEATURED NEWS

Sherwin-Williams Launches Solvent-Based Acrylic Fire Protection, FIRETEX® FX7002

FIRETEX FX7002 enables faster on-site fireproofing applications for 2-hour fire protection with low thickness requirements, high film builds and broad application windows.

Read the Press Release-

Benefits of FX7002

- High Wet Film Build = Fewer Coats

- Competitive Dry Film Thickness (DFT) Required

- Broader On-Site Application Window

-

FEATURED SOLUTION

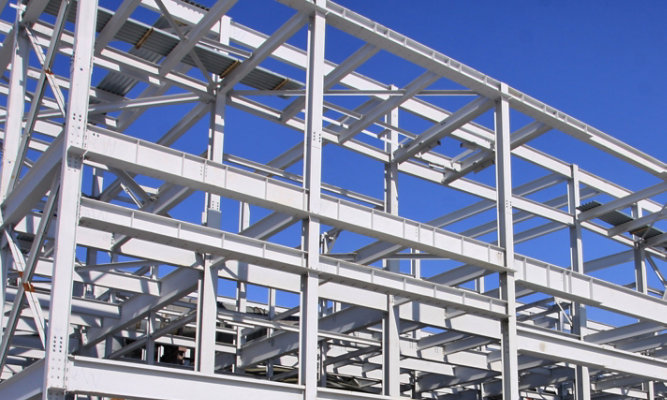

Innovative Solutions for Semiconductor Facility Construction

Rapid growth in the semiconductor industry involves building large-scale manufacturing facilities around the world. Sherwin-Williams Construction Solutions team is there, with the products, services and expertise needed to support these highly technical Capex megaprojects. Our industry-leading technologies help protect assets, extend lifecycles and improve work efficiency, resulting in safer, faster and simpler builds.

Get the Semiconductor Info Guide-

Construction Solutions

A SAFER environment, a FASTER build, and a SIMPLER process for new construction.

-

Semiconductor Facility Coatings

View Sherwin-Williams protective coatings for Semiconductor Facilities

Explore the Resource Page

Discover More

Industry Expertise and Innovation

Find latest news, industry thought leadership and product information.

Sherwin-Williams Protective & Marine delivers world-class industry subject matter expertise, unparalleled technical and specification service, and unmatched regional commercial team support to our customers around the globe. Our broad portfolio of high-performance coatings and systems that excel at combating corrosion helps customers achieve smarter, time-tested asset protection. We serve a wide array of markets across our rapidly growing international distribution footprint, including Bridge & Highway, Fire Protection, Flooring, Food & Beverage, Marine, Oil & Gas, Power, Rail, Steel Fabrication, and Water & Wastewater.